The Innovation Hangar prioritizes hosting exhibits of new technologies. Until February 2017 we had a UC Berkeley student-designed solar car on display in our public atrium; this vehicle dated from the early 1990s. The proliferation of newer materials and design techniques have provided the need for a newer, sleeker, more efficient prototype. Enter Joe Contreras, an SF State engineering major who heard of the Hangar's solar car project from David Caditz, the project's Director of Development. He informed his friend Cody Estes, who reached out to fellow students Ryan Eads and Jisung Kim to see if they wanted to partake in the project. They met with Caditz as a group and decided they wanted to get fully involved. Others were initially involved as well, but as Estes said, it didn't go so smoothly at first.

“We created a Society (called the Solar Electric Vehicle Team, or SEVT) at State because some people were saying they were committed to the project but wouldn't communicate effectively, didn't realistically have the time, and sometimes would just disappear,” he said. "Creating the SEVT Society allowed us structure for our project, credibility, and a true replication of how professional companies operate in the real world.”

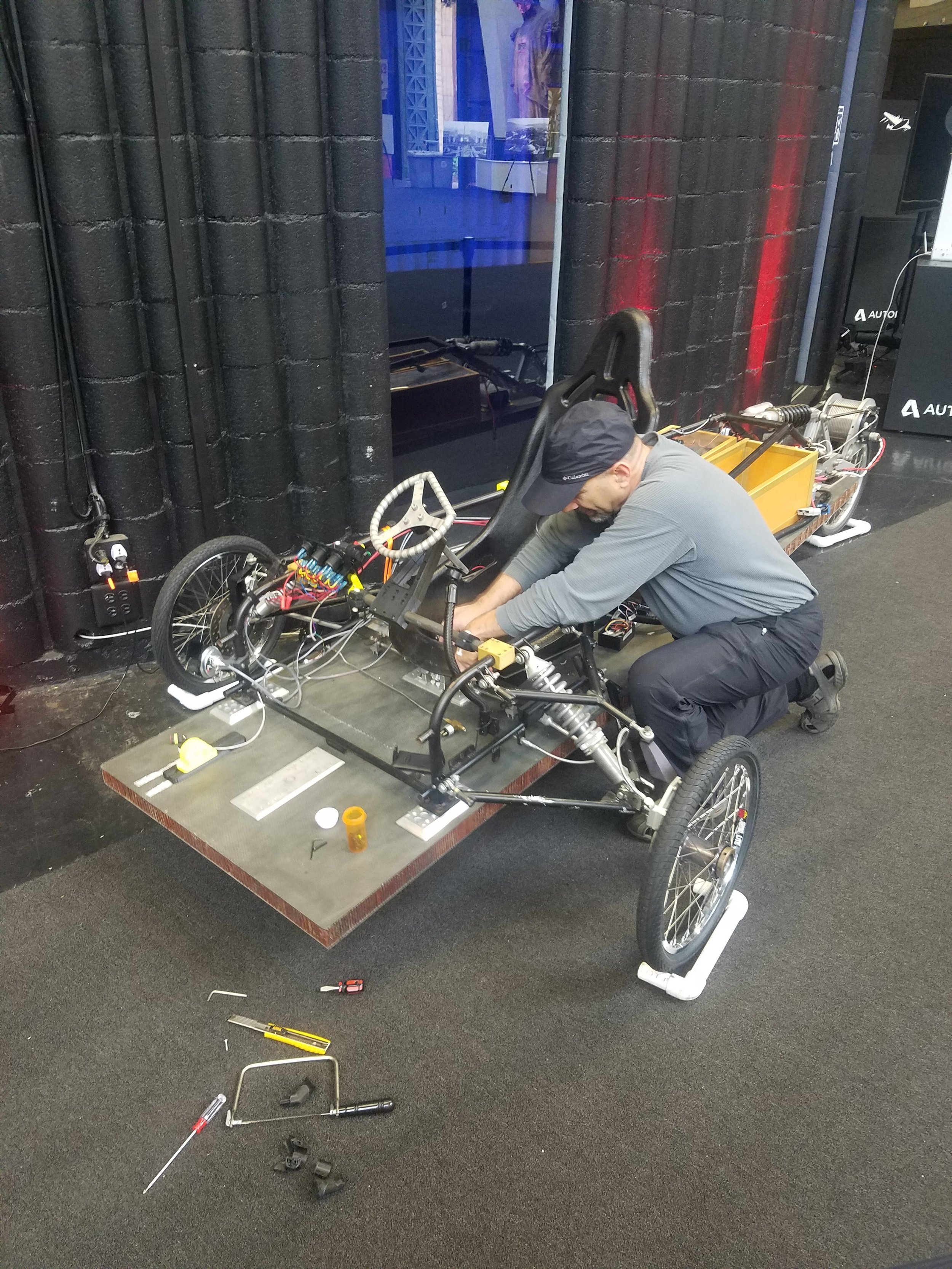

Project Supervisor David Caditz at work on the Solar Car prototype in the iHangar's public atrium.

Estes, Eads, Kim and Contreras all attend SF State and come from a variety of backgrounds, which provides the team with ample versatility. “Building a solar car takes up all aspects of engineering: Electrical, for the battery management system, peak power tracker, running wires, and setting up the solar arrays properly and effectively; Mechanical, for the steering column, stress analysis, breaks and shocks; Computer, which goes hand-in-hand with Electrical on the microcontrollers used for processing the battery management system, peak power tracker and coding user interfaces as well as setting up networks throughout the car,” Estes said.

Estes says the finances needed to build an efficient and up-to-date solar electric vehicle are copious, yet, the materials required for the physical prototype cost roughly a third of their value in the early 1990s due to the advancements in technology over the past two decades. In addition, the team has received funding from many companies such FLUKE, SolidWorks, IEEE, Sierra Circuits, TechShop, 3D Systems and more, all of which—as of January 2017—add up to around $65,000 dollars, he said, adding that the team is using a Gofundme.com page to gather donations from the public at large as well. “Our current goal is $100,000, mostly due to the construction of our body, our solar arrays, traveling with the car to and from the race destination, and the race entry fees.”

“In July, we are going to Texas to race in the Formula Sun Grand Prix. In order to enter this race there are a lot of regulations that we need to meet and follow that are listed inside the FPGA’s regulation manual, which is 50 pages long. We’ll be competing against other collegiate teams with way more experience than us, and way more money,” he said.

The team has a lot of praise for the iHangar, with Estes commenting: “The Innovation Hangar has been more than generous with donating us a reserved space at their facility. It is spacious and full of advanced and interactive activities—and with a cafe and a seating area, we don't need to go anywhere else for drinks or a break. Whenever we need some fresh air, we just go for a walk around the Palace of Fine Arts, which is an incredible privilege as well. The iHangar has also donated some materials and power tools for the foundation of our body, starting us off on our project.”

A unique aspect of the Solar Car's construction is the usage of parts created using a 3D printer housed on-site at the iHangar. David Caditz operates the printing software AutodeskFusion and Solidworks, exporting the necessary design files into .stl (StereoLithography) format for production on a CURA Type A printer—a piece of hardware that can be seen by the public in action in iHangar's atrium. Other members of the team operate the printer as well. Having the Type A as a part of their production process allows them to save both time and money, simply by providing them a cheap means to create their own materials.

The Type A printer used to produce parts for the car is also on display in the iHangar's public atrium.

After the team finishes building, testing, then eventually racing their prototype, they will make additional tweaks to have it up to par with where they want it to be as an alpha product. But more important to the team is the spiritual feeling of accomplishment upon the project's completion, and knowing it was they, a group of young SF State students, who designed and built this device. “Even if it our car doesn't perform at the rate that we want it to—we want it to be 'SF State driven,' meaning we want most of the parts made by our team and members. With the right money, you can buy the cream of the crop devices, batteries, and make the best solar car out there—but we aren't about that,” Estes said. “We want the car to reflect what we can do as students representing not just San Francisco State University, but San Francisco itself. Right now it is all new to us, but with the help of David Caditz, who is also our mentor, we are making our unique visions a reality .”

For more information about the SF State Solar Car project, please visit their iHangar page and their facebook page. As for updates on the project's progress, stay tuned to our blog.